Method of measurement:

Contact (point-based systems)

-

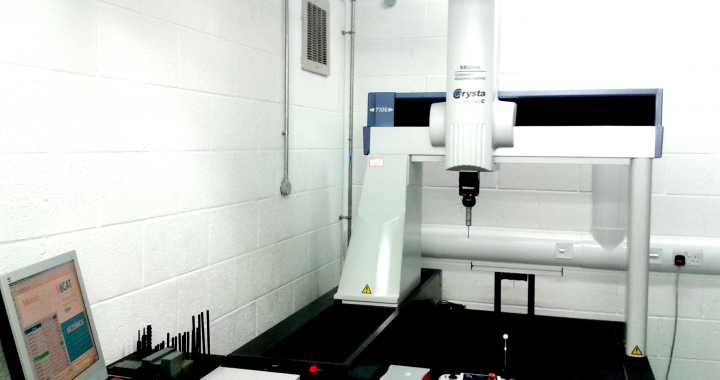

- Coordinate Measurement Machine

- (+) High accuracy measurement

- (+) Good for measurement of geometrical features:

- Diameter of Holes

- Diameter of Pins

- Cylindricity

- Roundness

- Coaxiality

- Concentricity

- (-) Restricted measurement area

- (-) Operated under temperature-controlled environment

- (-) Component to be measured must be allowed to be stabilized at that temperature

- (-) Access to certain features may cause problem

- (-) Speed of measurement – cycle time due to reposition

- (-) Less points for calculation of edge detection (done through intersection of planes and other features)

- Articulated Arm

- (+) Ideal for gauging

- (+) User friendly

- (+) Portability

- (+) Good for industrial shop floor application

- (+) Good for measurement of geometrical features:

- Diameter of Holes

- Diameter of Pins

- Cylindricity

- Roundness

- Coaxiality

- Concentricity

- (-) Restricted measurement area

- (-) Manual operation

- (-) Speed of measurement

- (-) Less points for calculation of edge detection (done through intersection of planes and other features)

- Coordinate Measurement Machine

- Non-contact

-

-

- Optical method – (Based on image processing, using backlight, direct light, and ring light)

- (+) Infinite number of points – edges are detected directly

- (+) Acceptable accuracy

- (+) Speed of measurement:

- one picture one measurement

- feature recognition

- ideal for real time statistical analysis such as SPC

- (+) Good for parts with small features

- (-) Good for measurement of flat parts only where parts can be measured in silhouette

- (-) Sensitive on dirt and dust, parts need to be clean before measurement

- (-) Hard to measure low contrast parts such as dark or white parts as well reflective surfaces

- Optical method – (Based on image processing, using backlight, direct light, and ring light)

-

-

-

- Laser scanning (Stripe based systems)

- (+) creates number of point clouds at one scan

- (+) no contact = no deformation on elastic parts like at contact method

- (+) good for clay models

- (-) point clouds must be patched together to create representation of an object

- (-) some materials absorb or in a way laser goes under surface, and measure surface underneath it, generating misleading results

- (-) Humidity affects performance

- Handheld:

- (+) good for scanning long parts

- (+) portability

- Mounted on CMM:

- Mounted on Articulated Arm:

- (-) for long parts the station needs to be moved

- Laser scanning (Stripe based systems)

-

-

-

- White light scanning (Area based systems)

- (+) Size of the area (up to several metres) scanned at once

- (+) Good for scanning small objects

- (+) Robustness and Portability makes the ideal for most demanding environments

- (-) Presence of holes can be problem, where is need on depth and shape

- White light scanning (Area based systems)

-

References:

[1] https://www.develop3d.com/reverse-engineering/a-guide-to-3d-measurement-technologies

[2] Understanding Optical Measurement Quality Digest / April 2009 (p.32 – p.35)