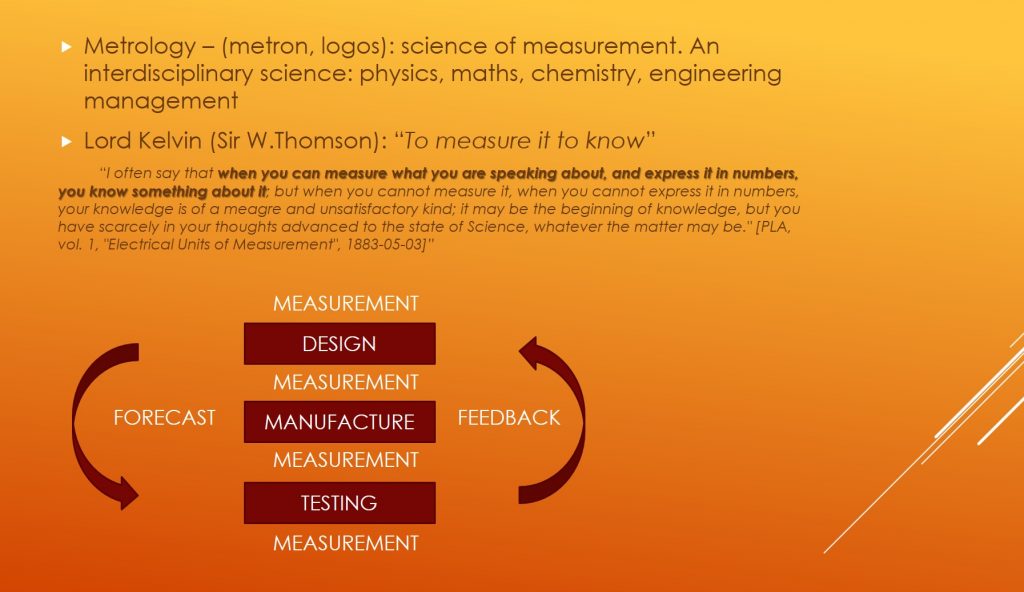

Before we dive in to point out about importance of metrology, I would like to take a chance and explain the meaning of the word “Metrology”. Metrology word comes from ancient Greek as a combination of two greek words Metron and logos, Metron = measure logos= behind argument. In modern world understanding is a Science of measurement. Often Metrology is interchanged wrong way with more well known and used word Meteorology, which is a science dealing with Earth’s atmosphere. But if that helps, then this science is also using knowledges and equipments, devices to measure quantities. The center point is measurement and everything what is related to measurement. As Lord Kelvin said “to measure, to know”.

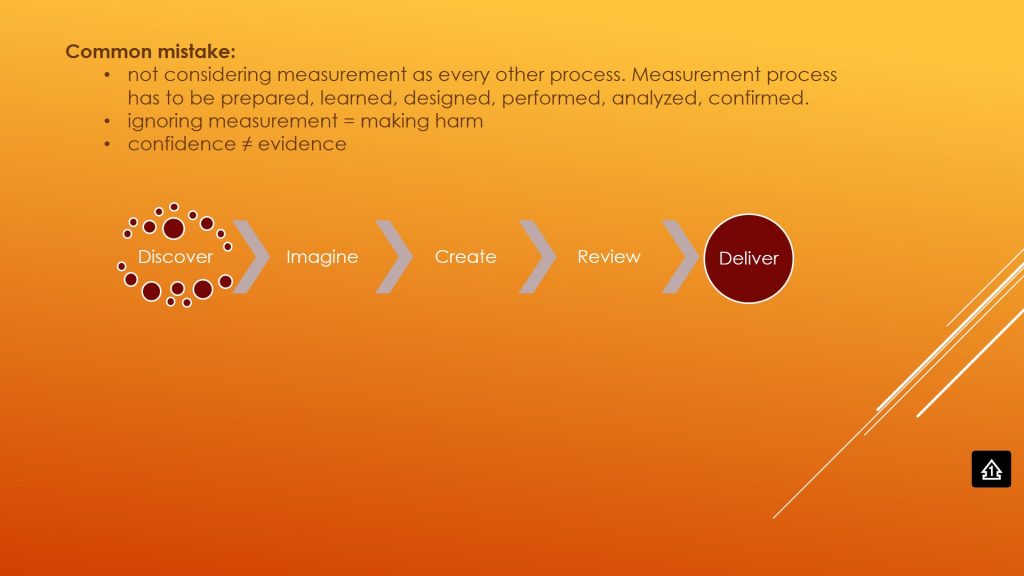

The goal is to express by numbers what we are speaking about. The end game would be to remove whatever doubt about the subject of our “topic” and being objective. Metrology today became our hidden part of our life. We go to the shop and measure, sit in car and measure, waiting for a bus, we measure, it is such an obvious act, that the only way to realize it’s importance, if we don’t measure. In manufacturing, either during product development or in mass production, in every stage of the project measurements needs to be done to make a meaningful decision. Unfortunately many managers, usually those one with none engineering background underestimate the importance of measurement and they consider it as a single act. But measurement is like every other process, it needs to be learned, prepared, designed, performed, analysed and conformed in order to trust measurement result. Ignoring measurement means putting under risk or making harm.

When someone mention advance manufacturing, my first thought are machines equipped with laser beam, milling machines and forging machines with very fine movement to remove material and produce a part, eventually a final product, or completely different approach called additive manufacturing represented by 3D printer machines, adding materials. All these machines have sensors build in, connected through central process unit to give instruction to actuators to do the job. Basically all advanced manufacturing machines are advanced because of their embedded measurement systems. They are known as CNC machines (Computer Numerically Controlled). These machines gathering datas into structures, using various mathematical algorithms to evaluate measurements and making decisions during productions.

After production, quality control will be the next step. Advanced machining technology demanding for more advanced measurement systems. CMM machines are known and used for 30 years but there still room to improve this method, although went through a big development using better probing systems. But there are on the list other methods of measurements by using multiaxis robots, articulated arms, laser interferometry, computer tomography and so on.

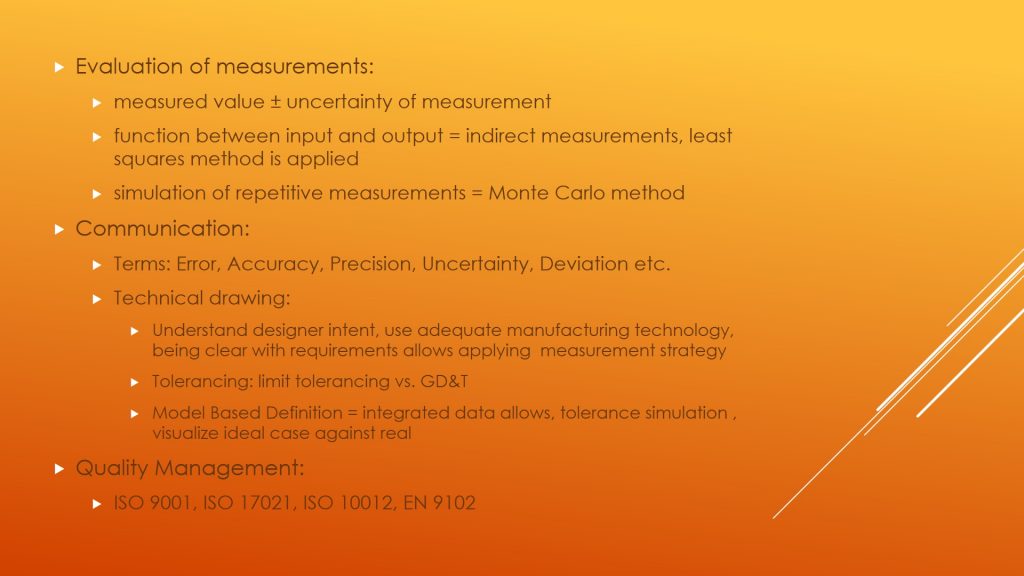

All these equipments are wasted if there knowledge is lacking from not knowing and feeling other fundamentals, like differences between terms like error, accuracy, precision, deviation. Being happy with the value of measurement without having a clue about level of confidence called measurement uncertainty what is taking into account all influence quantities of measurement, is not a good idea, as well. To express function between input and output quantities, various mathematical methods are used, such as least squares method or best fit, or for simulation of measurement Monte Carlo method.

Communication is very important, we need technical drawings, ie. to understand designer intent and customer specification. Different tolerancing methods deliver different results, recognize benefits of GD&T tolerancing, use Model Based Definition represented by 3D CAD model, which gives us an opportunity to visualize differences between ideal and real case, to see where we are.

One of the biggest influence on measurement is a human. To exclude humans completely from measurement is not possible, but rules can be set up. Those rules controlled by Quality management system such us ISO 9001, ISO 17021, ISO 10012, EN 9102. These rules specially important in mass production to monitor process and see what is going on and making adjustments to meet specifications. In order to reach this stage, everybody on his level has to knowledgeable, well trained, and if something happens they are able to make immediate corrective actions.

As a conclusion from above mentioned, to reach success, is not only a pure hard work is needed, we have to be smart too. The value of metrology, and process of measurement, in every process, not only in advanced manufacturing is the success. Success means to produced what yesterday was not possible, to save our environment, to be faster, to save finances. Putting effort and give high relevance to measurement, means being smart, to use result and making good decisions means being smart.